Microencapsulation

We define microencapsulation as a procedure where liquid or solid compounds are coated with a layer of polymers. The microcapsules obtained by this process have a diameter ranging from millimeters down to few micrometers. The encapsulated substances are defined as core materials.

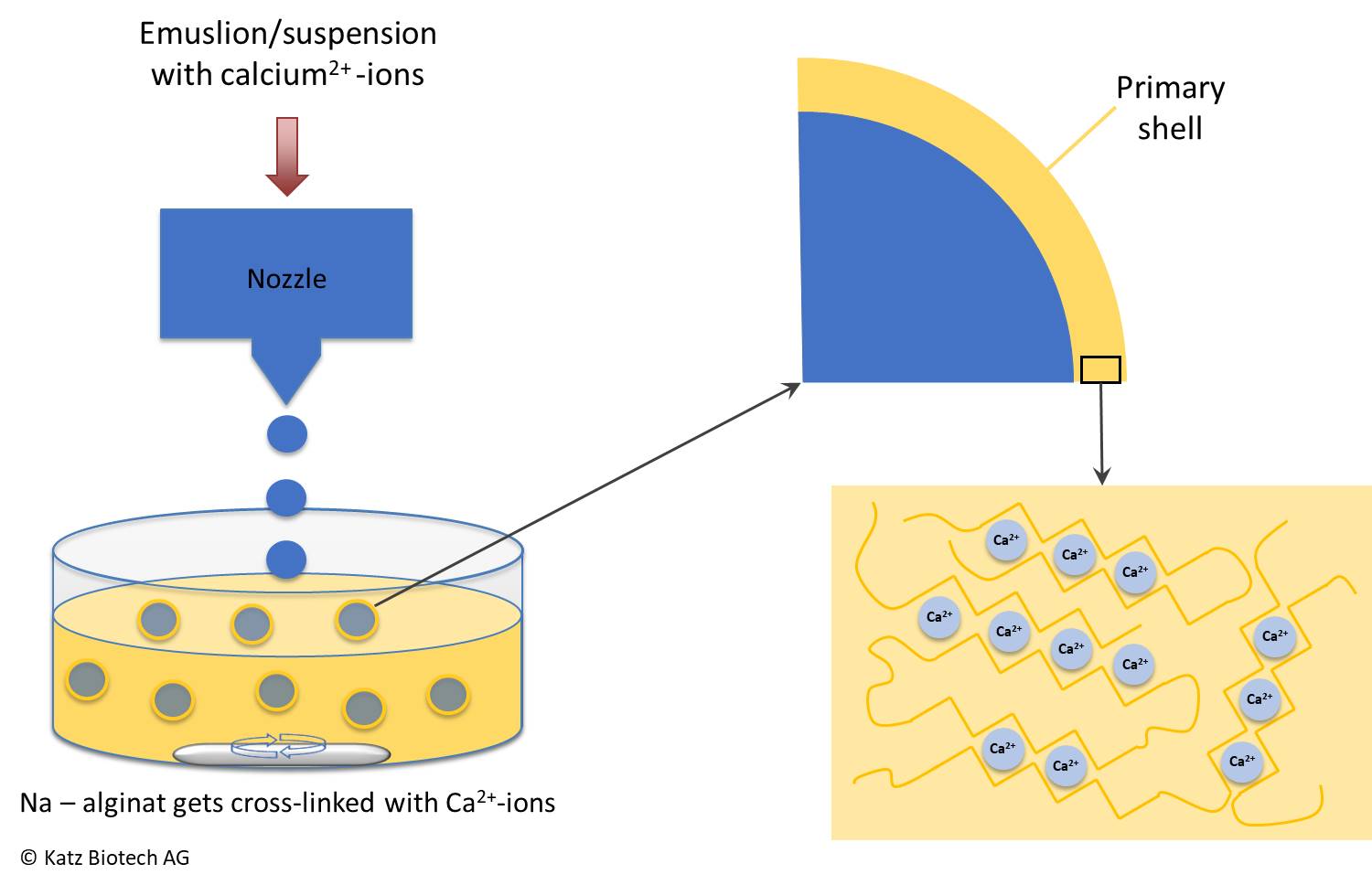

Type I - aqueous emulsion/ - suspension as core material

The microcapsules are produced via an extrusion procedure. The core material is pumped through an inner nozzle where the compressed air is passed out through annular gap of the nozzle leading to the formation of a droplet. Afterwards, the droplet is immersed into a solution where it is coated with a polymer network, for instance alginate. Alginate is known to be crosslinked by calcium ions in the so-called egg-box model.

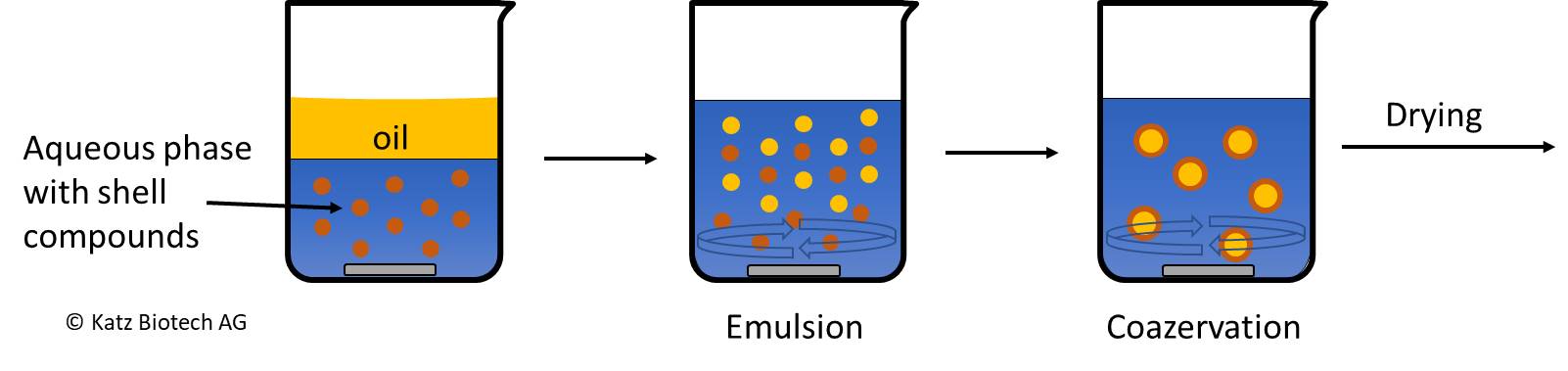

Type II - oily emulsion/ - suspension as core material

The type II microcapsules are made by coacervation. In this process the core material is emulsified in an aqueous solution which contains the coating material.

After mixing, the coating material accumulates at the interface between oil and water and coats entirely the whole surface of the capsule. After the cross-linking of the coating material, the capsules are dried through ventilation.